PRODUCT INTRODUCTION

In industrial production, belt conveyors is the link that connects each production equipment, ensured the continuity and automation of the production process. In the crushing industry, the belt conveyors produced by our company are widely used to transport loose materials or finished items Suitable for various hard and soft ores, such as: limestone, calcite, dolomite, barite, talc, calcium carbonate, gypsum, bentonite, glass, etc.

WORKING PRINCIPLE

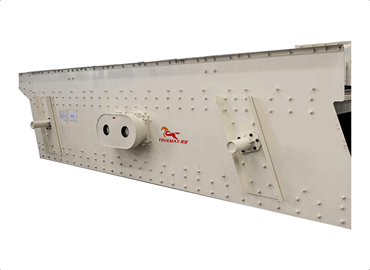

It moves according to the principle of friction transmission. According to the requirements of the conveying process, it can be conveyed in a single unit, or it can be composed of multiple belt conveyors or a horizontal or inclined conveying system with other conveying equipment to meet the needs of different layouts of operation lines.Belt conveyor is mainly composed of frame, conveyor belt, belt roller, tensioning device, transmission device, etc. The fuselage is made of high-quality steel, and the frame is formed by the height difference between the front and rear legs, and the plane is inclined at a certain angle. The rack is equipped with belt rollers, idlers, etc., used to drive and support the conveyor belt. There are two ways to drive the reduction motor and the electric drum.

PRODUCTION ADVANTAGES

1.For possible slippage between different materials and the belt conveyor, a "herringbone" belt conveyor can be provided to enhance the stability of the belt conveyor.

2.According to different conveyed process requirement , can use in a single unit, or can be composed of multiple belt conveyors or a horizontal or inclined conveying system with other conveying equipment.

3.Can be used in the range of ambient temperature -20°(to +60°(, the temperature of the conveyed material is below 50°(, with high adaptability.

4.Suitable for various hard and soft ores, such as: limestone, calcite, dolomite, barite, talc, calcium carbonate, gypsum, bentonite, glass, etc. |